In-House Quality Lab for Critical Measurements

Fab Masters is an ISO 9001:2015 and ISO 14001:2015 certified company. Parts manufactured in a plant whose Management System of Quality and Environmental is certified as being in conformity with ISO 9001:2015 and ISO 14001:2015 by Intertek.

Quality is achieved through parts and process monitoring, XR charting, incoming raw material layouts, optical measuring, visual welding inspection, thread gauge inspections and final inspections. Any special inspections or testing is performed per customer instructions. All measuring instruments are tested and certified, traceable to the National Bureau of Standards.

Fab Masters is an experienced 3rd party manufacturer of UL and ETL approved parts.

We maintain quality by:

- Material certification

- Incoming inspections

- Continuous monitoring throughout manufacturing process

- Final inspections prior to product release or shipping

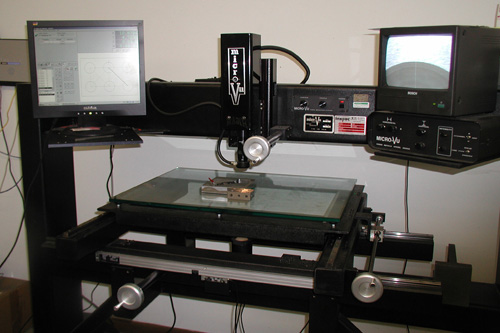

To augment our fabrication services, we maintain our own in-house Quality Lab. Duties of the five-member staff are divided among CNC machining, welding, ITAR, and ISO inspections. These inspections are executed with the use of our Micro-Vu (Video Optical Comparator), calipers, versa, height and pin gauges. thread gauges and protractors on 1st piece inspections to machined parts, in-process checks and inspections on incoming extrusions. Additionally, new Inspec software for the Micro-Vu has greatly increased efficiency on these inspection procedures.

Quality Assurance Equipment

An optical comparator is an instrument that projects a greatly magnified image of a part feature onto a screen for examination, to compare the shape, size, and location of its features. The new software enables a part, when laid-out, to be seen on a separate monitor that makes checking distances and true positions more accurate. Files can then be saved or emailed directly to customers. A print file can also be imported for simultaneous comparison to part. In addition, the ability to write programs increased accuracy and saves time.

Calibrations and inspections on welded and cut parts are executed on our Coordinate Measuring Machine (CMM), the fully automated LK G-90C. Manually measuring highly machined parts used to take hours of inspection time – now, same parts are measured in 30 minutes automatically on LK G-90C.

The LK G-90C operates on the same premise as a computer numeric controlled (CNC) machining center (its automatic). You program it; it measures the part from the same point every time, using the same X-Y-Z grid as a CNC to determine a position on the worktable. The LK CAMIO software allows development of programming inspection routines directly from CAD models, running off-line so as not to disrupt the operation of the CMM. The LK G-90C takes our Quality Department to the next level, faster inspection times, higher accuracy, and will free up quality staff.

Quality Statement

Fab Masters Company, Inc. is to consistently provide parts and services that meet or exceed the quality expectations of our customers. To achieve this we will monitor Request for Quotes, Sales, Scrap Reduction, On Time Delivery and continually improve our Quality Management System which will enable all employees at Fab Masters to do the job right the first time, every time.

Environmental Statement

Fab Masters Company, Inc. is committed to: Protection of the environment, prevention of pollution, fulfilling our compliance obligations and continual improvement of our environmental management system to enhance environmental performance through our environmental objectives, business processes, and reduce our adverse impact on the environment.

Our job is to consistently protect, utilize and manage our natural resources in order to prevent pollution in the place we work and the earth we inhabit.