Do you currently rely on sheet metal to create products for your company? If so, you should think about using aluminum extrusions instead. Outside of the fact that using aluminum extrusions to manufacture products is typically less expensive than using sheet metal, you can also create products in significantly less time when you choose to go with extrusions.

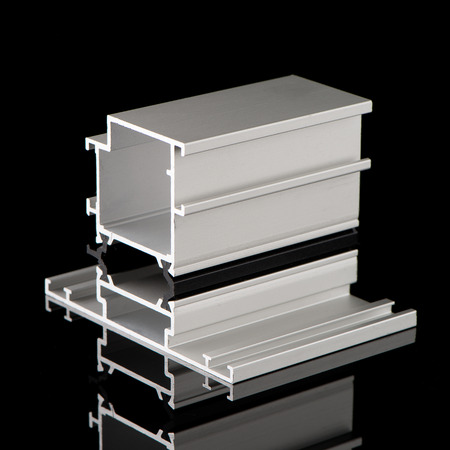

Extrusions vs. Sheet Metal: How You Can Save with Extrusion