Do you currently rely on sheet metal to create products for your company? If so, you should think about using aluminum extrusions instead. Outside of the fact that using aluminum extrusions to manufacture products is typically less expensive than using sheet metal, you can also create products in significantly less time when you choose to go with extrusions.

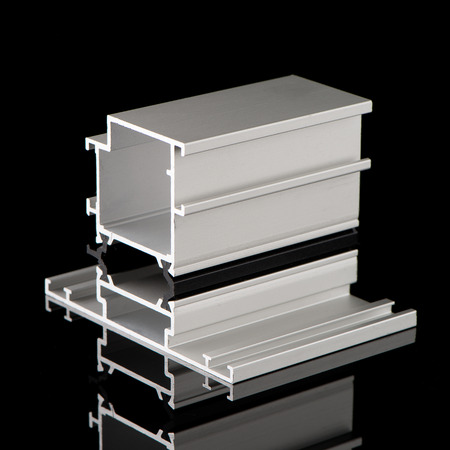

Aluminum extrusion is a technique that involves taking aluminum alloy and transforming it into a wide range of products, and it has proven to be very effective for many companies. One of the biggest benefits of using aluminum extrusions – besides just the cost and the speed at which products can be manufactured – is the strength that comes along with them. Aluminum is known for being incredibly strong, and yet it weighs just one-third of a metal like steel, which makes it easier to transport and use for all kinds of different applications.

Aluminum extrusion is a technique that involves taking aluminum alloy and transforming it into a wide range of products, and it has proven to be very effective for many companies. One of the biggest benefits of using aluminum extrusions – besides just the cost and the speed at which products can be manufactured – is the strength that comes along with them. Aluminum is known for being incredibly strong, and yet it weighs just one-third of a metal like steel, which makes it easier to transport and use for all kinds of different applications.

Aluminum can also be used to make products that are just about any size. Whether you need a small part made for a custom machine or something significantly larger, you will be able to do it with aluminum extrusion. Additionally, aluminum extrusions have a high resistance to corrosion, plus a flexibility and adaptability that you won’t get with other metals. Plus, through punching and stamping, you can still create a wide range of components with customization where you need it using an extrusion process.

Businesses can save a significant amount of money by moving to an extrusion production while also finding time savings in the more rapid pace of part production. Many companies have found that aluminum extrusion is the way to go and have decided to move beyond using sheet metal to create their machined products.

If your business is looking to gain an advantage while still creating quality products, Fab Masters can help you decide whether aluminum extrusions or sheet metal would be the better choice for you. Contact us at 877-320-2280 today to find out more about aluminum extrusion and how it can help your company.